This is how we manufacture

In our administration, the production and in the dispatch department we have round about 90 employees working on your calendars. Below you find information about the most important machines in our manufacture.

Pre-press:

Suprasetter 105 with Heidelberg workflow

Fuji Luxel V-9600 with Fuji XMF workflow

Formproof on EPSON large format printer

Digital-Proof on EPSON STYLUS PRO 4880

Print:

Heidelberg Speedmaster SM 52

Heidelberg Speedmaster CX 102

Heidelberg Speedmaster 74-2-PH with 2 inking units and turning system

KBA RAPIDA 105 L with 5 inking units and one chamber blade coating system, Densitronic inking-control and CIP4 data-import

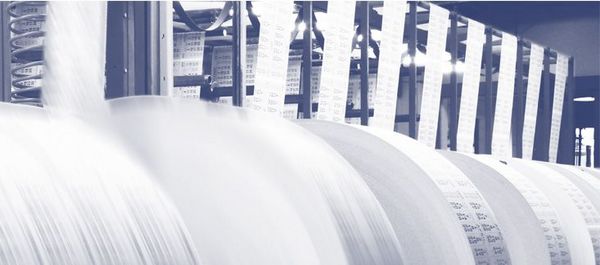

Goebel Optiforma m, 6-colours UV-web offset-print

Goebel Optiforma m, 8-colours UV-web offset-print

Ricoh C901 (digital print)

Further processing:

Gathering machine Theisen & Bonitz

Bielomatik JUMBO collator

RENZ wire binding

Iberica automatic punching press

Sanwa automatic punching press

"Original Heidelberg Zylinder" (OHZ)

"Heidelberger Stanztiegel"

"Buschstanze"

POLAR cutting machine 115 XT Autotrim

Environment protection:

- We use mineral-oil free printing inks, linseed-oil-based and with reduced alcohol.

- The production of printing plates works without water and chemicals.

- The indispensable machine lubricants are free of poison and heavy metals and do not contain allergens. We use water-soluble dispersion coatings.

- Inline colour-measurement reduces the average waste by 100 to 150 sheets per job and thus lowers CO²-emission.

- Thanks to intelligent controlling the ancillary components of the machines only turn on if necessery to save energy.

- With the modern machines we can reduce the use of isopropyl alcohol by half though the productivity increases.

- Automatic washing units for blankets, inking units and printing cylinders consume less detergents and reduce emission of Volatile Organic Compounds (VOC).